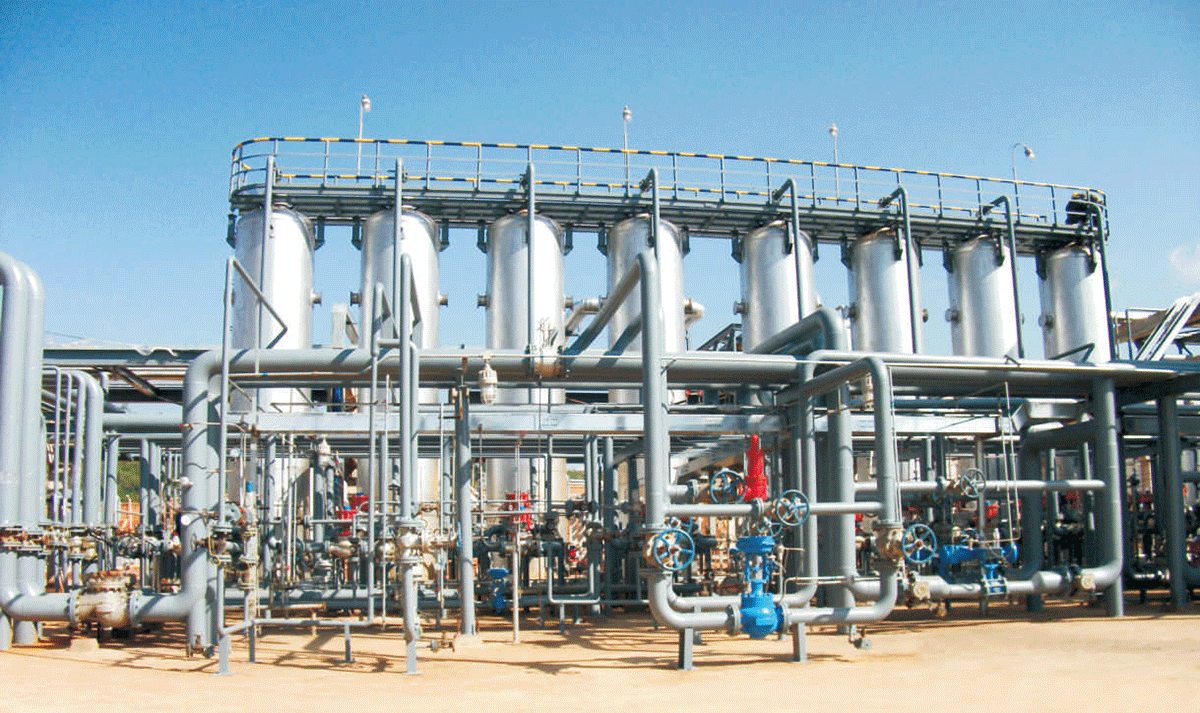

The adsorption capacity of adsorbents for ethane (C2) and hydrocarbons above C2 varies with pressure after the feed gas enters the adsorption tower of PSA unit. Under pressure, the hydrocarbon impurities above C2 in the feed gas are adsorbed, and the unsorted gas (purified gas) acts from the outlet of the adsorption tower. The adsorbed impurities are desorbed and desorbed from the adsorbent and regenerated at the same time. At least four adsorption beds are circulate to achieve continuous output of purified gas

Working principle:

The adsorption capacity of adsorbents for ethane (C2) and hydrocarbons above C2 varies with pressure after the feed gas enters the adsorption tower of PSA unit. Under pressure, the hydrocarbon impurities above C2 in the feed gas are adsorbed, and the unsorted gas (purified gas) acts from the outlet of the adsorption tower. The adsorbed impurities are desorbed and desorbed from the adsorbent and regenerated at the same time. At least four adsorption beds are circulate to achieve continuous output of purified gas

Feed gas:

natural gas

Control mode and characteristics

Control mode:

The SPA device is controlled by the controller and meter. The controller can select DCS, FCS and PLC control system according to the scale and control requirements of the SPA device.

Characteristics:

It not only realizes the conventional control of the system, but also realizes the expert control and adaptive optimization control of arbitrary combination and switching of multiple towers, which not only improves the operational flexibility of the device, but also ensures the long-term, stable and safe operation of the PSA device.

Service:

Provide patents and proprietary technology, provide the design for complete equipment

Feed gas:

Pressure: 0.3~0.8MPa

Temperature:Normal temperature

Output product: purified gas

C2:≤100ppm

C3:≤30 ppm

CH4 recovery rate: 70~90%

system△P:≤0.10MPa

Output temperature: normal temperature

Note: CH4 recovery rate is related to raw material composition, pressure and CO2 purity

By product: degassing

output pressure:≤0.02MPa

Output Temperature:≤40℃